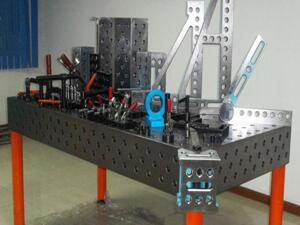

鑄鐵平板(鑄鐵平臺)的(de)用(yong)途:鑄鐵(tie)平臺可(ke)(ke)以用(yong)于檢驗機械零(ling)件平面(mian)(mian)度,平行度,直線(xian)(xian)度等(deng)形(xing)位(wei)公差(cha)的(de)測量基準,也可(ke)(ke)用(yong)于jingmi零(ling)件的(de)劃線(xian)(xian)和測量,實驗,鉚焊,焊接(jie),基礎(chu),工(gong)作臺等(deng),工(gong)作面(mian)(mian)采用(yong)刮研(yan)工(gong)藝,工(gong)作面(mian)(mian)可(ke)(ke)以設計圓(yuan)孔(kong),長方孔(kong),方孔(kong),T型槽(cao),U型槽(cao),V型槽(cao).

查看詳情

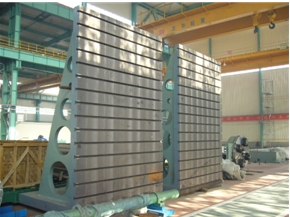

落(luo)地(di)(di)(di)平(ping)板別(bie)名:地(di)(di)(di)平(ping)板、地(di)(di)(di)平(ping)臺(tai)、落(luo)地(di)(di)(di)平(ping)臺(tai)、落(luo)地(di)(di)(di)鏜床(chuang)(chuang)(chuang)工(gong)(gong)(gong)(gong)作臺(tai) 落(luo)地(di)(di)(di)平(ping)板用(yong)途(tu):落(luo)地(di)(di)(di)平(ping)板是與數控落(luo)地(di)(di)(di)鏜銑(xian)床(chuang)(chuang)(chuang)配套使(shi)用(yong),主要(yao)用(yong)于支(zhi)撐加(jia)工(gong)(gong)(gong)(gong)工(gong)(gong)(gong)(gong)件。主要(yao)用(yong)于機床(chuang)(chuang)(chuang)加(jia)工(gong)(gong)(gong)(gong)工(gong)(gong)(gong)(gong)作平(ping)面(mian)使(shi)用(yong),上面(mian)有(you)孔和T型槽,用(yong)來(lai)固(gu)定工(gong)(gong)(gong)(gong)件,和清理加(jia)工(gong)(gong)(gong)(gong)時產生的鐵屑。常見(jian)的機床(chuang)(chuang)(chuang)工(gong)(gong)(gong)(gong)作臺(tai)如(ru):落(luo)地(di)(di)(di)鏜床(chuang)(chuang)(chuang)工(gong)(gong)(gong)(gong)作臺(tai)

查看詳情

鑄鐵工作臺主(zhu)(zhu)要適用(yong)于(yu)各種檢(jian)驗(yan)(yan)工作,度(du)測量用(yong)的(de)基準(zhun)(zhun)平(ping)面(mian),主(zhu)(zhu)要用(yong)于(yu)機械工件檢(jian)驗(yan)(yan)測量中(zhong)的(de)基準(zhun)(zhun)面(mian),檢(jian)查零件的(de)尺寸度(du)或行為偏(pian)差,并可作jingmi劃線,在機械制造檢(jian)驗(yan)(yan)中(zhong)是不可缺(que)少的(de)平(ping)面(mian)基準(zhun)(zhun)量具.

查看詳情

我公司生(sheng)產的(de)(de)(de)檢驗平臺是經過(guo)兩次研(yan)磨(mo)加(jia)(jia)工而成的(de)(de)(de),另外為了防止斷(duan)裂我們(men)還(huan)采取有利(li)于自由(you)收縮的(de)(de)(de)結構,或加(jia)(jia)強易(yi)產生(sheng)裂紋處的(de)(de)(de)結構強度,這一方面的(de)(de)(de)改進也就更加(jia)(jia)提升了我們(men)公司檢驗平臺的(de)(de)(de)性能,在市場的(de)(de)(de)競爭上,也有了更強有力的(de)(de)(de)后盾! .

查看詳情機床鑄造(zao)床身(shen)經過 制模(mo)—模(mo)型(xing)涂刷-制作砂型(xing)-鑄造(zao)毛坯-清砂-退(tui)火(huo)處理-粗(cu)加工-退(tui)火(huo)-數控機床精加工-人工刮研(yan)-處理外(wai)觀-包(bao)裝、入庫 等十多道工序(xu)制作而成。每道工序(xu)都經過研(yan)檢部門的層層把關。

鑄鐵平臺材料為HT200-300,QT400-600,采用刮研工藝,工作面上可加工V形、T形、 U形槽、燕尾槽、圓孔、長孔等,大型鑄鐵平臺是用于工件、設備檢測、劃線、裝配、焊接、組裝、鉚焊的平面基準量具。

機床鑄件產品采用樹脂砂、消失模鑄造。材質為灰鐵HT250-300,硬度高、耐磨性能好。經過 制模—模型涂刷-制作砂型-鑄造毛坯-清砂-退火處理-粗加工-退火-數控機床加工-人工刮研-處理外觀-包裝、入庫 等十多道工序制作而成。每道工序都經過研檢部門的層層把關。

- 操逼視頻免費觀看:機床鑄件缺陷產生的原因

發布時間:2024-11-07

- 操逼視頻免費觀看:機床鑄件鑄造工藝和澆注準則

發布時間:2023-03-15

- 操逼視頻免費觀看:鑄造鑄鐵工作臺時應注意的事項有哪些

發(fa)布時間:2022-08-15

- 操逼視頻免費觀看:刮研是什么工藝?檢驗平臺為什么要刮…

發布時間(jian):2022-07-09

- 操逼視頻免費觀看:鑄鐵平臺的維護確保質量的方法

發布時間:2022-04-04